23/11/2024

Introduction

When it comes to keeping your home warm and your water hot, regular boiler servicing is key. Recently, I carried out a comprehensive boiler service in Goole on a Worcester Bosch CDi Classic Combi. This wasn’t your typical annual service—this boiler hadn’t been serviced in years, so it needed extra care, including replacing key seals and gaskets that Worcester recommends changing every five years.

In this post, I’ll walk you through the entire process, including which parts were replaced and why. If you own a Worcester CDi boiler, you’ll find this a useful guide to understanding what’s involved in a major service and what should be checked or replaced to keep your boiler running efficiently.

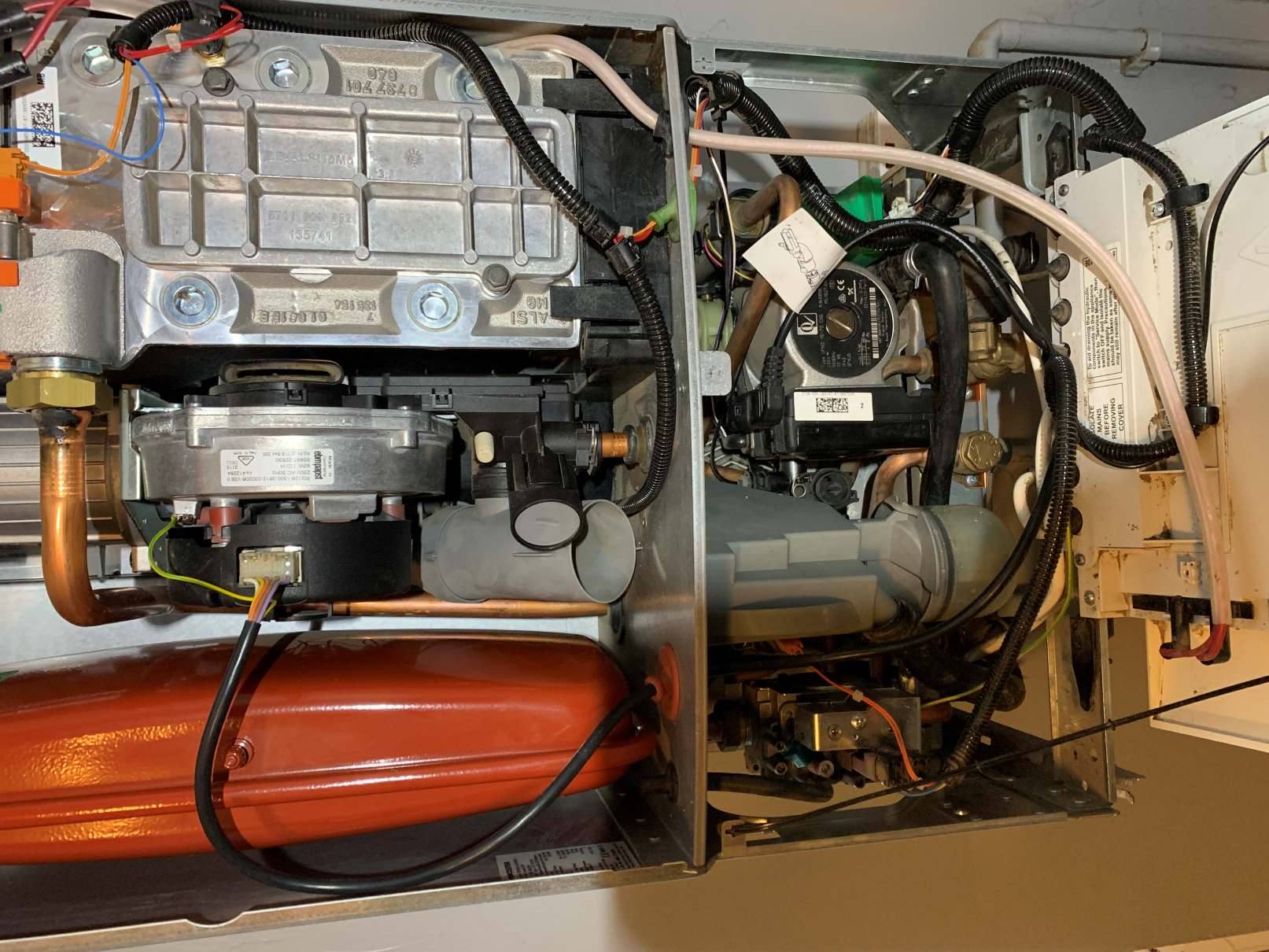

Initial Boiler Inspection

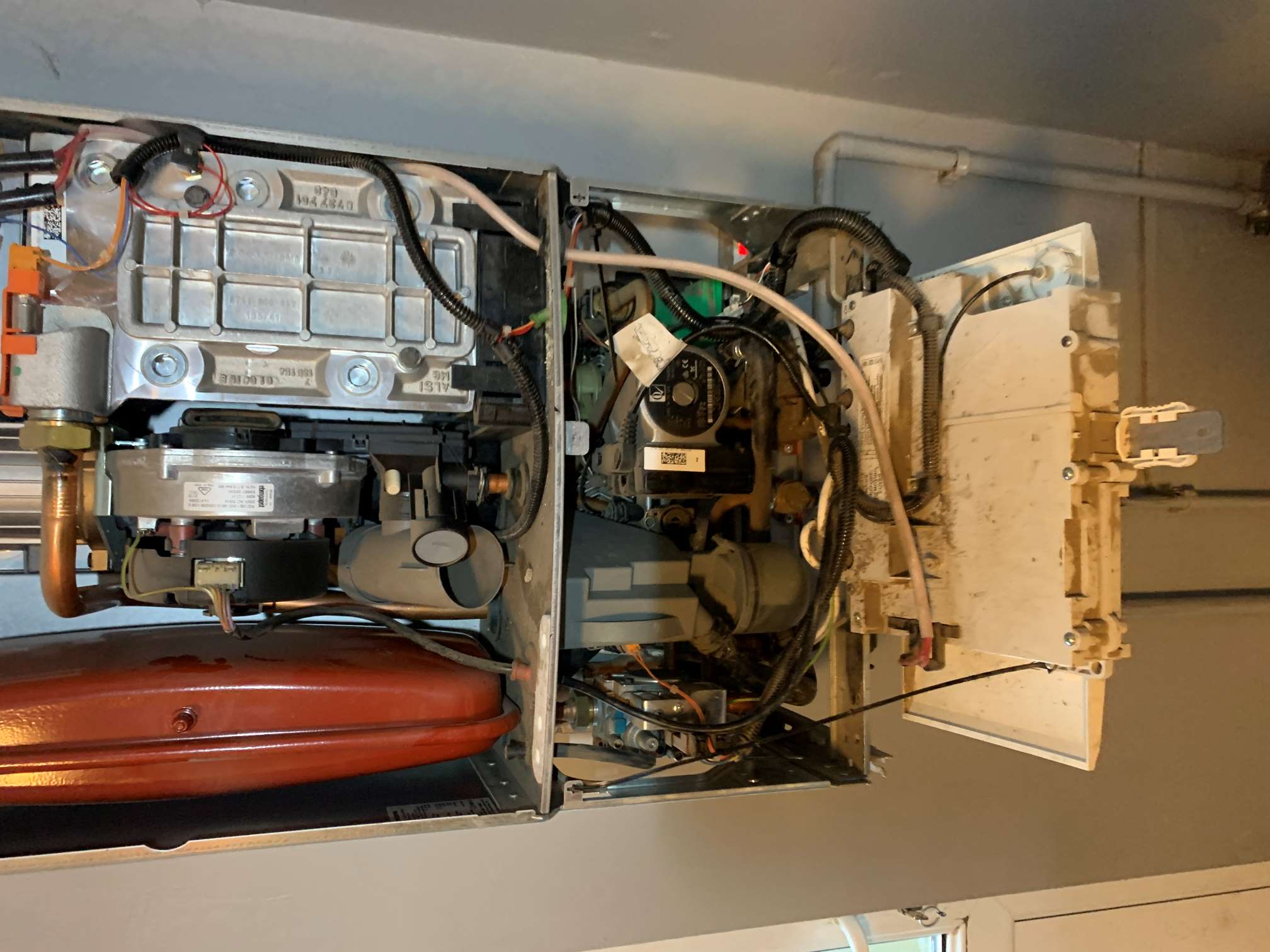

Here’s a photo of the Worcester Bosch CDi Classic when I first arrived. As you can see, the boiler was thick with dust, a clear sign that it hadn’t been serviced in quite some time.

Recharging the Expansion Vessel

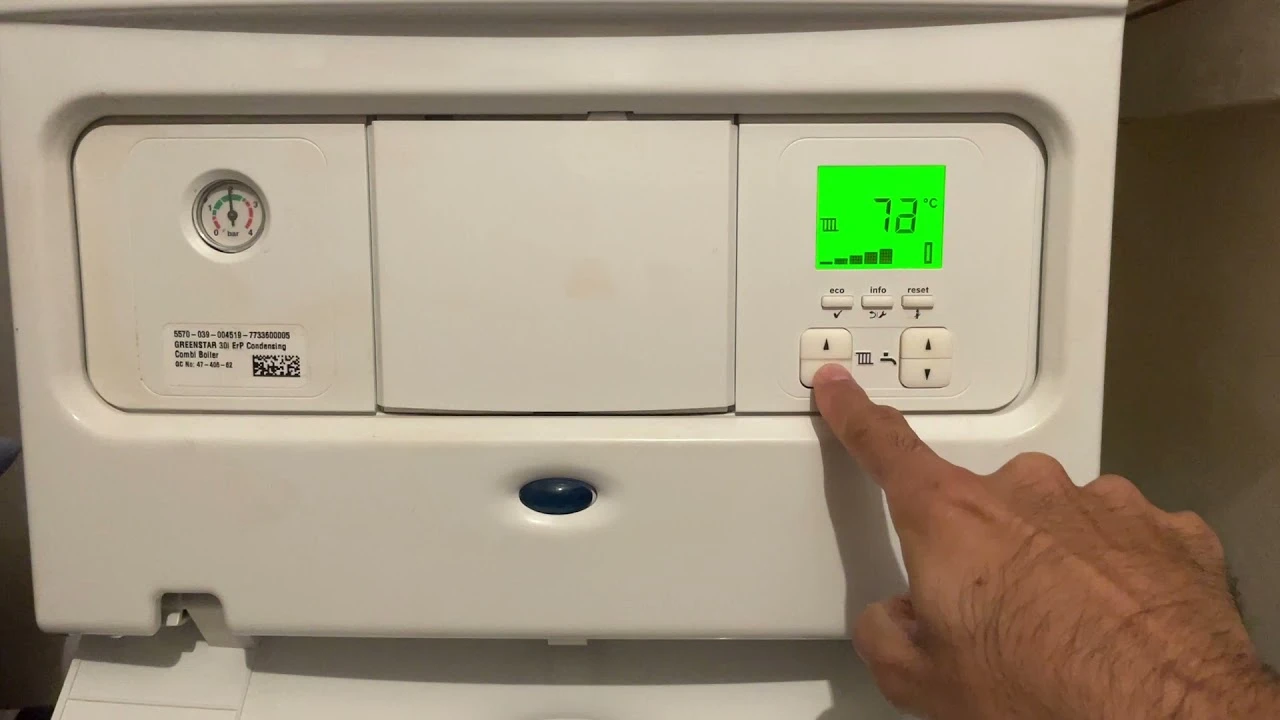

The first step in the service was to drain the boiler and recharge the internal expansion vessel to 1 bar. This is a crucial task that should be included in every boiler service—not just during major ones—but it’s often overlooked. The expansion vessel plays an important role in maintaining consistent pressure in your heating system, and neglecting it can lead to pressure loss issues over time.

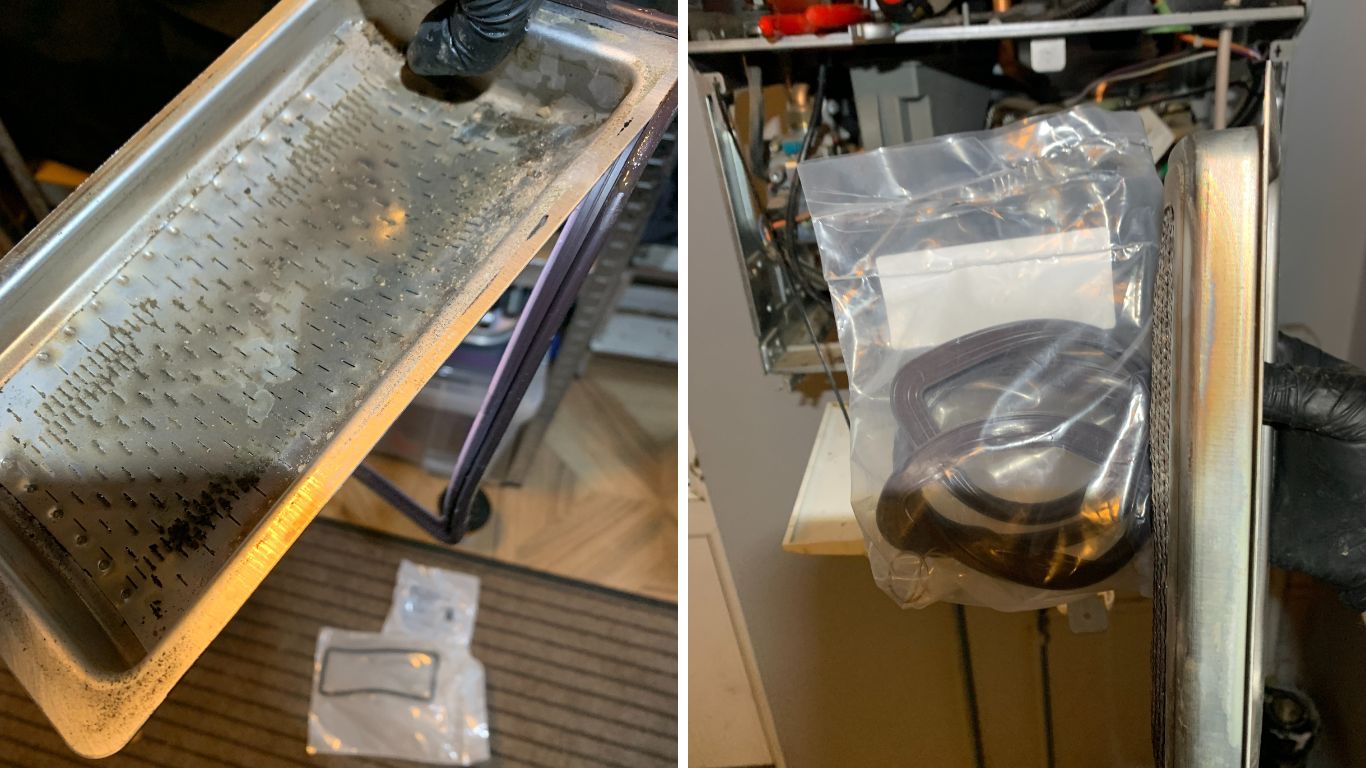

Once the expansion vessel was correctly pressurised, I moved on to cleaning the MagnaClean filter. This Magnetic filter helps to trap sludge and debris from the heating system, keeping it running efficiently. Over time, the filter can become clogged, so giving it a clean every service is essential.

Cleaning the Heat Exchanger

I started by removing the burner and flushing the primary heat exchanger with water to clear out the by-products of combustion that had built up. I also removed the combustion chamber access cover and used the Worcester Bosch servicing tool to clean between the air channels of the heat exchanger.

When re-instating the combustion chamber access cover, it’s important to check the condition of the seal. Worcester recommends replacing the seal every 5 years, and I replaced it during this service as I had no evidence of its age. If the seal is worn or damaged, it can leak the products of combustion, which is a safety concern.

Worcester also recommends replacing the set of electrodes every 5 years. As there's no safety concern by not changing them, I typically assess their condition on each major service, and only replace them if necessary, as they can be fairly costly, around £60. In many cases, I can clean them up with a bit of wire wool, and they’re good to go for another few years. During this service, however, I found it necessary to replace them.

Cleaning and Reassembling the Burner

Next, I cleaned the burner matrix to remove the debris build-up.

After that, I re-assembled the burner, replacing the burner seal, fan seal, and bearing plate. I replace these seals at every major service to ensure the system remains sealed and functioning properly.

The bearing plate is another component I recommend replacing after 5 years. More often than not, around the 7-10 year mark, it tends to tear, as was the case with this boiler. If left unchecked, a torn bearing plate can lead to a breakdown, so I always replace it proactively during major services.

Cleaning the Condensate Trap and Boiler Internals

I then cleaned out the condensate trap, which is an essential part of every service. Over time, this trap can become clogged with debris caused by the by-products of combustion, potentially leading to blockages and faults if not maintained.

After that, I gave the inside of the boiler a thorough clean using a combination of a cloth and compressed air. I find compressed air particularly effective for cleaning between components where a cloth can’t reach, ensuring the boiler is free of dust and debris.

Performing Safety Checks

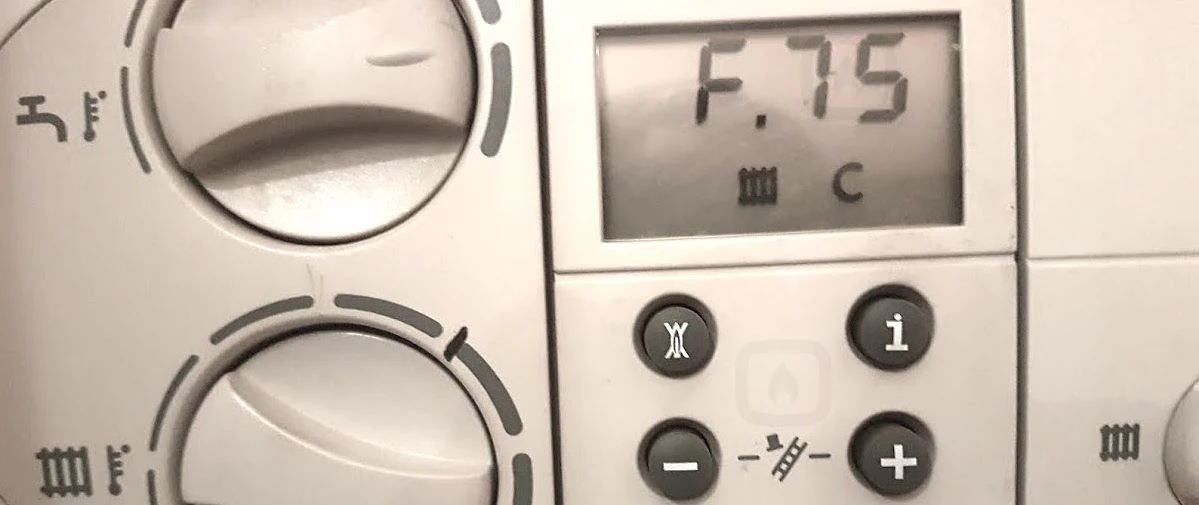

The final stage of the service was completing a series of safety checks to ensure the boiler was operating safely and efficiently. These included:

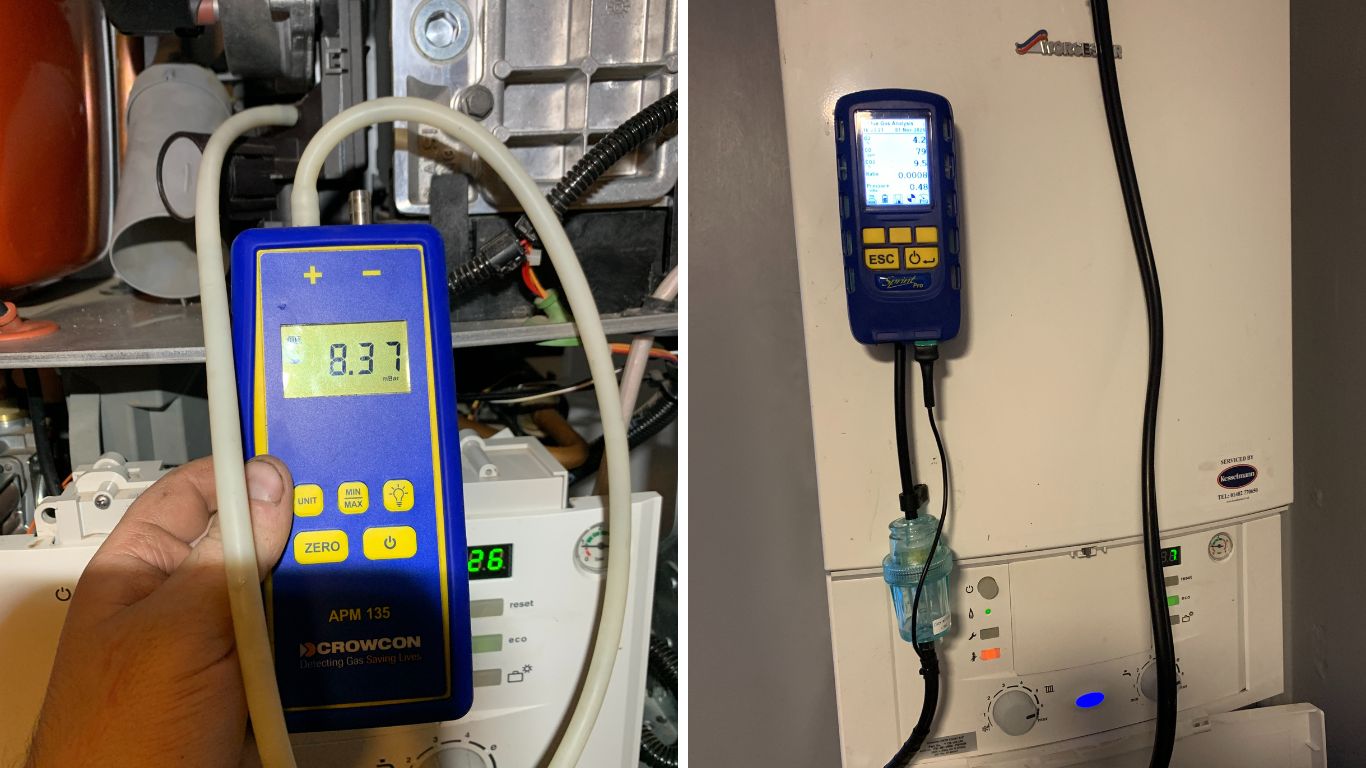

Gas Integrity Check: Using a gas leak detector to ensure there were no leaks in the system.

Gas Inlet Pressure Check: Verifying that the boiler was receiving the correct gas pressure for optimal performance.

Fan Pressure Test: Checking the fan pressure to confirm the correct operation of the combustion process.

Flue Gas Analysis: Measuring the levels of carbon monoxide and carbon dioxide in the flue gases to ensure the boiler was burning fuel safely and efficiently.

These checks are a critical part of any Worcester boiler service.

Outcome and Final Thoughts

Both the customer and I were pleased with the results of this boiler service. The boiler looked far cleaner after I had finished, and I managed to bring it back up to a good condition so that ongoing servicing will be cheaper for the customer.

The Worcester Bosch Classic range are my favourite boilers. In my opinion, their build quality and reliability are far superior to many other brands and models. With proper care and regular servicing, these boilers can easily last 20 years or more.

By giving this boiler the attention it needed, it’s now ready to continue providing efficient and reliable heating for years to come.

Need Your Boiler Serviced?

If your boiler hasn’t been serviced in a while or you want to ensure it’s running safely and efficiently, I’d be happy to help. Whether it’s a standard service or a more comprehensive one like the example above.

To book a professional service or for more information, get in touch with us today. Simply give us a call or book an service here.

We provide boiler servicing in Hull, East Yorkshire & North Lincolnshire

Written by : Paul Tozer