08/03/2025

Magnetic boiler filters have become a common addition to modern central heating systems, with many homeowners and heating engineers debating their true value. While a high-quality magnetic filter can be beneficial, it is not a one-size-fits-all solution. In this guide, we will explore what magnetic filters do, their benefits and limitations, and when they should be used in conjunction with other maintenance practices such as powerflushing and inhibitor treatment.

What Is a Magnetic Boiler Filter?

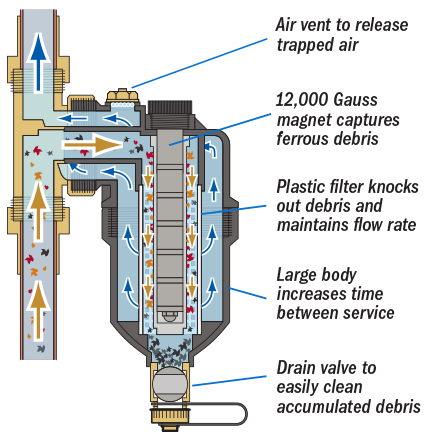

A magnetic boiler filter is a device fitted to a central heating system to capture and remove sludge, debris, and metallic particles from the water circulating through the system. The primary component of these filters is a strong magnet, usually made from neodymium, which attracts and traps ferrous (iron-based) particles. Some models also include mesh filters to catch non-magnetic debris.

The purpose of a magnetic filter is to help prevent the build-up of sludge, which can cause blockages, reduce system efficiency, and contribute to boiler breakdowns. However, while they can be an effective preventative measure, they are not a complete solution for an already contaminated heating system.

Benefits of a Magnetic Boiler Filter

1. Prevents Sludge Build-Up

Over time, central heating systems accumulate sludge formed from rust, dirt, and scale. Magnetic filters help capture these particles before they circulate through the system, reducing the risk of sludge build-up.

2. Prolongs Boiler and Component Lifespan

By preventing sludge from reaching the boiler, pumps, and radiators, a magnetic filter can help extend the life of these components, reducing the likelihood of expensive repairs or replacements.

3. Improves System Efficiency

A cleaner system allows water to circulate more efficiently, reducing strain on the boiler and improving heat distribution. This can lead to lower energy bills and a more comfortable home.

4. Reduces Risk of Boiler Breakdowns

Boilers can become blocked or damaged by sludge and debris. A magnetic filter helps reduce this risk by trapping contaminants before they reach critical components.

5. Enhances the Effectiveness of Inhibitor Chemicals

Inhibitors are chemicals added to the heating system to prevent corrosion and sludge formation. A magnetic filter works alongside inhibitor chemicals by capturing any particles that form, keeping the system cleaner for longer.

Limitations of Magnetic Boiler Filters

While magnetic filters have their benefits, they are not a cure-all solution for heating system problems.

1. Not a Substitute for a Powerflush

If a heating system is already heavily contaminated with sludge, simply installing a magnetic filter will not resolve the issue. A powerflush—where a high-strength chemical cleaning process is used to remove sludge—is often necessary before installing a filter.

2. Dirt Can Still Get Through

Even high-quality magnetic filters cannot catch 100% of contaminants. Some debris, especially non-ferrous (non-magnetic) particles, can still pass through and clog up the boiler, leading to breakdowns.

3. Poor-Quality Filters Offer Little Protection

Not all magnetic filters are built the same. Cheaper, lower-quality models may have weak magnets or poor construction, meaning they are ineffective at capturing debris. A high-quality filter from a reputable brand is a much better investment.

4. Requires Regular Maintenance

A magnetic filter needs to be cleaned regularly to remain effective. If left unchecked, it can become clogged, reducing its ability to trap debris and potentially restricting water flow.

When Should You Install a Magnetic Boiler Filter?

Ideal Scenarios for Installing a Filter:

When installing a new boiler: A filter can help keep a new system clean from day one.

After a powerflush: If the system has been thoroughly cleaned, a magnetic filter helps maintain that cleanliness.

As part of routine system maintenance: Installing a filter can help prevent issues in systems that are in relatively good condition.

When a Filter Alone Is Not Enough:

If the system is heavily sludged up: A powerflush is needed first to clear out existing contamination.

If the boiler is already suffering from sludge-related failures: The boiler may require repairs before a filter can offer any benefit.

Choosing the Right Magnetic Boiler Filter

Not all filters offer the same level of protection. Here are some key factors to consider when choosing a magnetic filter:

1. Magnet Strength

A strong magnet is essential for capturing as many metallic particles as possible. Look for filters with neodymium magnets, as they are among the most powerful.

2. Build Quality

A well-built filter will last longer and provide better protection. Look for filters made from durable materials, such as brass or high-quality plastic, and avoid cheap, poorly constructed models.

3. Filter Size and Flow Rate

Ensure the filter is suitable for your heating system’s size and flow rate. Some models are designed for larger systems, while others are better suited for smaller domestic setups.

4. Ease of Maintenance

Choose a filter that is easy to access and clean. Some models feature quick-release mechanisms that make cleaning simpler.

Installation and Maintenance

Installing a Magnetic Filter

A magnetic filter is typically installed on the return pipe to the boiler, where it can capture debris before it enters the boiler. The installation process involves:

Shutting down and draining part of the heating system.

Cutting the pipework and fitting the filter.

Ensuring all connections are secure and leak-free.

Refilling the system and adding inhibitor chemicals if necessary.

Maintaining a Magnetic Filter

To keep a magnetic filter working effectively:

Check and clean it annually, ideally during a boiler service.

Remove trapped debris by opening the filter and wiping the magnet clean.

Inspect for wear and leaks to ensure it remains in good condition.

Are Magnetic Boiler Filters Worth It?

A high-quality magnetic boiler filter is a worthwhile investment for most central heating systems, but it is not a standalone solution. It should be seen as a preventative measure rather than a fix for existing sludge problems. If a system is already contaminated, a powerflush should be carried out before installing a filter.

A well-maintained magnetic filter, combined with regular use of inhibitor chemicals, can help keep a central heating system running efficiently and reduce the risk of costly boiler breakdowns. However, poor-quality filters are not worth the money, as they provide little protection and may fail to prevent sludge-related issues.

Ultimately, whether a magnetic boiler filter is worth it depends on the quality of the filter, the condition of the heating system, and whether it is used alongside other good maintenance practices. When installed and maintained correctly, a magnetic filter can play an important role in prolonging the life of a central heating system and ensuring it operates at peak efficiency.